Mesh fabric generally has two composition methods, one is knitting and the other is carding. Among them, the knitted warp-knitting mesh fabric has the tightest structure and the most stable state. The so-called warp-knitting mesh fabric is knitted fabrics with mesh-shaped holes.

Weaving principle

There are generally two weaving methods for woven mesh fabric: one is to use two sets of warp yarns (ground warp and twisted warp), twist each other to form a shed and interweave with weft yarns. The twisted warp is twisted on the left side of the ground warp by using a special twisted heddle (also known as half heald) and twisted to the right side of the ground warp after one (or three, or five) weft insertions. The mesh-shaped small holes formed by the interweaving of skeins and weft yarns are stable in structure and are called lenos; the other is the use of jacquard weaves or changes in reeding methods. Three warp yarns are used as a group to penetrate a reed tooth, and can also be woven. There are small holes in the fabric, but the mesh structure is unstable and easy to move, so it is also called false leno.

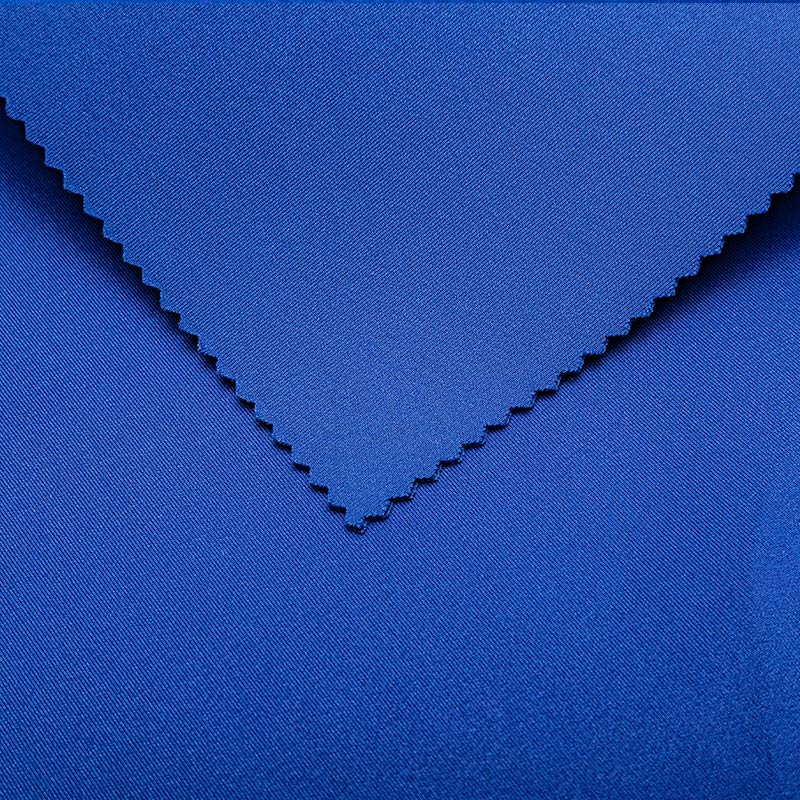

Fabric Features

Warp-knitting mesh fabric presents a six-sided air-permeable hollow three-dimensional structure (three-dimensional elastic support structure in the middle) with its unique surface double-mesh design and a unique structure in the middle (like X-90° or "Z", etc.). Make it have the following characteristics:

1. It has good resilience and has the function of cushioning and protection.

2. It has excellent breathability and moisture permeability. (The warp-knitting mesh fabric adopts X-90° or "Z" structure, with mesh holes on both sides, presenting a six-sided air-permeable hollow three-dimensional structure, free circulation of air and water, forming a hot and humid microcirculation air layer.)

3. Light texture, easy to wash.

4. Good softness and wear resistance

5. Mesh diversity, fashion style. The shape of the mesh is various, such as triangle, square, rectangle, rhombus, hexagon, column, and so on. Through the distribution of the mesh, it can present pattern effects such as straight bars, horizontal bars, squares, rhombuses, chain links, and ripples.

fabric application

Warp-knitting mesh fabric is also realized through skilled cutting, sewing, and auxiliary processing when making clothing. Warp-knitting mesh fabric first has sufficient gaps and has good moisture-conducting, breathable, and temperature-regulating functions; The raw material has wide adaptability and can be made into soft and elastic clothes; finally, it has good surface performance, good dimensional stability, and high breaking strength at the seam; it can be used as lining and fabric of special clothing, warp-knitted spacer fabric It can also be used to produce safety vests.

The warp-knitting mesh fabric has good warmth retention, moisture absorption, and quick drying. At present, some main applications of warp-knitting mesh fabric in leisure sports are sports shoes, swimming suits, diving suits, sports protective clothing, etc.

Used for sewing mosquito nets, curtains, lace; medical elastic bandages of various shapes; military antennas and camouflage nets, etc.